# What Is an Ore Pass in Mining?

An ore pass is essentially a mining shaft designed to transport ore and mining waste from different levels of the mine. It serves as a practical and efficient means to move materials and reduce the distance materials need to be hauled between various levels.

## Considerations for Building an Ore Pass

Ore passes leverage gravity to facilitate the movement of materials from one mine level to another. There are two primary methods for constructing an ore pass: the drill and blast method and the mechanical method.

The drill and blast method involves drilling a hole in the desired location of the ore pass, followed by placing explosives to create the passageway. On the other hand, the mechanical method employs a raise borer, a machine that excavates a circular tunnel between the mine levels.

When constructing an ore pass, miners take several factors into account:

- **Location**: The ore pass should intersect with mining levels to make it easier for workers to address potential blockages or hang-ups within the system. Hang-ups are a common issue in underground mining. Stress conditions and the type of rock must also be considered when selecting a location. If the ore pass is situated in an area with weak host rock, it may be more prone to hang-ups. Ideally, ore passes should be positioned away from the mining face to maintain the mine's structural integrity.

- **Length**: Longer ore passes are more vulnerable to wear and tear and are more expensive to construct. Typically, short ore passes ranging from 10 to 100 meters are built in mines, though some can extend up to 300 meters.

- **Dimensions**: The dimensions of an ore pass are determined by the shape of the opening and the size of the materials passing through it.

- **Shape**: Ore passes can be square, rectangular, or circular. Those created with a raise borer are usually circular.

- **Orientation**: Ore passes can be either vertical or inclined based on the mine layout, the materials being transported, and the degree of fragmentation of the material.

- **Support**: Ore passes can be reinforced with rebar and linings such as shotcrete.

## Types of Ore Pass Systems

In the mining industry, there are two main types of ore pass systems: the flow-through ore pass system and the full ore pass system.

For both systems, ore and waste are deposited into the ore pass and eventually reach the draw point, where the ore is transported by loaders, conveyors, or rail cars to an underground stockpile.

### Flow-Through Ore Pass System

In flow-through systems, ore is poured into the ore pass and flows down to the draw point.

This system is often used when the ore contains high levels of fines (fine particulates), which can lead to hang-ups in the ore pass. Continuous material flow prevents fines from settling, reducing the likelihood of blockages.

Flow-through systems are also used when broken rock is sent through mills at rates exceeding underground ore production in full systems. However, the constant flow of material through this system makes the ore pass more susceptible to damage, requiring regular maintenance, reinforcement, or even costly redesigns that can disrupt mining operations.

### Full Ore Pass System

In full ore pass systems, a certain amount of ore is kept in the ore pass at all times.

This system is employed to prevent degradation of the ore pass, avoid rock failures, and mitigate mining-related seismic events. However, there is a greater risk of hang-ups in this system because rock does not continuously flow through the ore pass. As a result, fines settle in the pass and oxidize, leading to blockages.

In a full ore pass system, the mill is constantly fed, making it challenging to maintain material levels. By extending draw times from the ore pass, these levels can be better managed.

## Ore Pass Monitoring

Regular monitoring of the ore pass is crucial to ensure its structural integrity, prevent mining-related seismic events, and avoid overfilling.

Mine personnel or drones are used to monitor and inspect the following aspects of an underground ore pass:

- Material levels

- Wall quality

- Liner quality

- Material control equipment

Routine inspections help prevent hang-ups and maintain mine safety. Neglecting to monitor an ore pass can lead to unexpected ore runs and hang-ups, potentially damaging equipment, compromising structural integrity, and endangering miners.

## Using Drones to Investigate Ore Pass Blockages

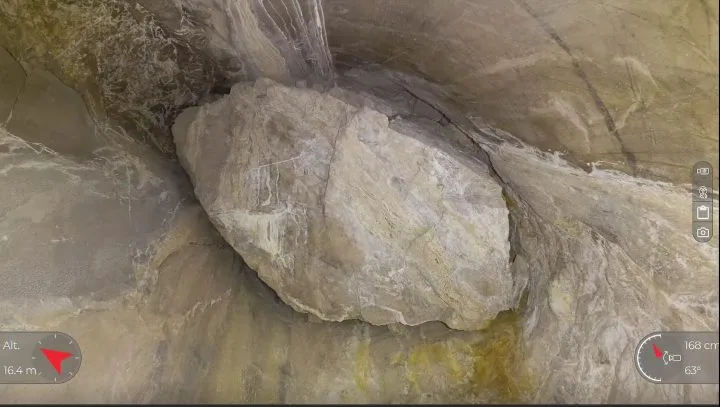

A blockage, or hang-up, in an ore pass can halt mining operations entirely. In 2023, personnel at a major mining operation in Colorado encountered a significant hang-up that blocked the entire ore pass, halting ore movement.

These blockages are often discovered near the truck chutes—where the ore exits the raise and is loaded onto trucks for transport to crushers. However, in this case, personnel couldn't spot anything in the truck chute, indicating the blockage was further up the raise, out of sight.

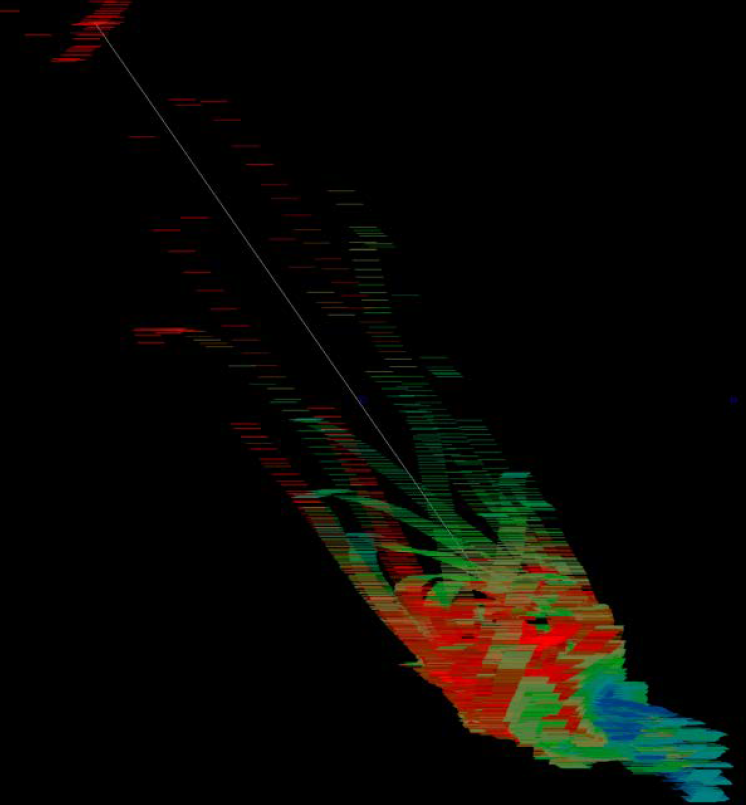

To locate the blockage, workers initially fed a CMS scanner into the raise through a small access hole in the chute. The scanner provided a low-density point cloud of the raise, revealing the approximate location of the hang-up to be around 27.5 meters (90 feet) up the raise. They then drilled exploratory holes of varying lengths from a higher production level into the ore pass, inserting a small sewer camera to pinpoint the exact location and nature of the blockage.

Despite finding the mass in the ore pass using the CMS scans, attempts to clear it by drilling holes, dropping small charges, and retrieving debris were unsuccessful for two months. Eventually, the area of the mine became depleted, and upper management decided to abandon the site without fully understanding the blockage.

The solution lay in the Elios 3, a specialized drone for mining. The Elios 3 offers pilots real-time visual feedback and a 3D Live Model on their tablets, enabling them to see both what the drone sees visually and how the surrounding environment appears in a 3D model simultaneously.

Given these capabilities, mine personnel believed the Elios 3 might be the ideal tool to determine the location and nature of the hang-up.

Within just ten minutes, the Elios 3’s geolocational data on its 3D Live Map pinpointed the exact location of the blockage in the raise.

Learn more about how the data from the Elios 3 survey was used to investigate and resolve the ore pass hang-up.

This machine is suitable for producing leno bag or mesh bag for various kinds of vegetables and fruits such as carrot, potato, corn, onion, garlic head, orange and apple etc.

This type mesh Circular Loom with crossing device, frequency inverter, auto stop when warp or weft is broken or weft is finished, digital length counter, it is featured in the compact structure, easy maintenance, low power-consumption and high efficiency.

Compared with the old type mesh circular loom, it saves 90% Spare Parts and 35% power with more stable running performance, precise warp weaving, the warp can turn 180° Even if the warp is circle yarn, this machine can show its excellent performance.

Leno Mesh Circular Loom,Vegetables Packing Mesh Leno Bags Machine,Pp Woven Leno Mesh Circular Loom,Circular Mesh Loom For Mesh Bag