How Mine Drones Are Improving Safety and Optimizing Mining

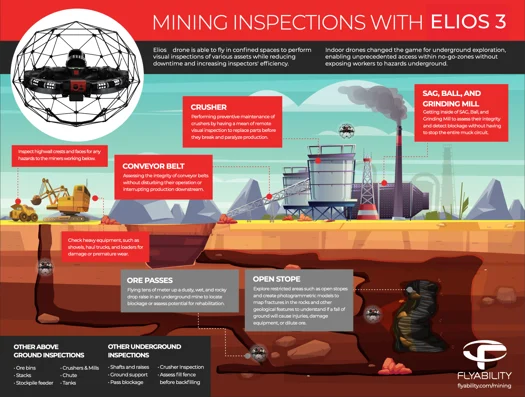

Mine drones are revolutionizing the mining industry by providing a safer, more efficient, and cost-effective way to gather critical data. As drone technology continues to evolve, the applications for mine drones are expanding rapidly. A mine drone is a specialized aircraft designed for use in both underground and surface mining environments. These drones are used for tasks such as stockpile measurement, surveying, mapping, and inspections, including ultrasonic thickness testing. Mining is inherently dangerous, with unpredictable conditions that can change quickly. While drones cannot eliminate all risks, they can access hazardous areas where human workers cannot go, significantly improving safety. One of the key advantages of mine drones over consumer-grade models is their ability to operate without GPS, which is often unavailable in deep underground or remote mining locations. The mining industry has embraced drone technology due to its ability to enhance data collection, improve safety, and reduce costs. Here are six ways mine drones are being used today: Volumetric monitoring involves calculating the amount of material in stockpiles, such as overburden, ore, or other materials. Traditional methods of measuring these large piles are time-consuming and inaccurate. Mine drones equipped with advanced software can generate 3D models using photogrammetry or LiDAR scans, allowing for precise volume calculations. This data helps track changes in stockpiles over time, reducing waste and improving operational efficiency. Drones can also estimate how much backfill is needed for a stope, making it easier to plan future operations. Mining environments can be extremely dangerous, with risks like unstable rock formations, gas leaks, and dust explosions. Drones allow for remote inspections, reducing the need for workers to enter hazardous areas. In surface mines, drones monitor stockpile stability, while in underground mines, they navigate tight spaces to detect blockages and structural issues. Drones like the Elios 3 are specifically designed for confined and challenging environments, offering real-time 3D mapping and sensor-based hazard detection. Drones play a crucial role in assessing drilling and blasting activities. Before any work begins, 3D models created from drone data can serve as a baseline for comparison after the operation. This helps identify potential hazards and evaluate the effectiveness of different blasting techniques. These models also provide situational awareness, enabling safer decision-making before workers enter an area. Drones are essential for monitoring and planning various aspects of mining operations. They help assess haulage roads, inspect equipment, ensure site security, and monitor environmental impacts. For example, drones can check the condition of conveyor belts and crushers, reducing maintenance costs and downtime. They also support environmental monitoring by tracking tailings dams and detecting leaks or runoff, helping to minimize ecological damage. Exploring new mining sites and developing existing ones is a costly and risky process. Drones offer a safer alternative by navigating inaccessible areas and gathering critical data without putting workers at risk. They are especially useful for inspecting old or disused parts of a mine, providing valuable insights for future operations. The Elios 3 is particularly suited for underground exploration due to its ability to function in low visibility and poor air quality. Drones are used to inspect processing plants, checking for wear and tear on machinery without interrupting production. They can capture high-resolution images and videos, measure thickness with ultrasonic sensors, and monitor temperature and structural integrity. This allows for proactive maintenance, reducing downtime and increasing operational efficiency. The benefits of using drones in mining are numerous. They improve safety by reducing the need for human entry into hazardous areas, increase efficiency through faster data collection, and lower costs by minimizing manual labor and downtime. Other advantages include improved accuracy in stockpile measurements, enhanced security, and better environmental monitoring. With continuous advancements in drone technology, the future of mining looks even brighter. Watch the Elios inspect and map an obstructed ore pass:  Among the many drones available, Flyability’s Elios 3 stands out for its durability, functionality, and ability to operate beyond line-of-sight. It is designed for indoor and confined spaces, where traditional drones may struggle. With a unique spherical cage, the Elios 3 is collision-tolerant, making it ideal for navigating dark, dusty, and narrow mine shafts. Its dual thermal and 4K camera, along with a powerful lighting system, ensures accurate and detailed data collection. Whether you're conducting inspections, mapping, or collecting data, the Elios 3 offers a reliable solution for modern mining operations. Flyability Elios 3 Specs / Features: The WingtraOne GEN II is a fixed-wing drone designed for long-range surveys and efficient mapping. It features a vertical takeoff and landing (VTOL) system, allowing it to operate in challenging terrain. With a flight speed of 16 m/s (36 mph) and 59 minutes of flight time, it covers up to 272 acres per flight. Its 42-megapixel camera captures high-resolution images, and the onboard PPK GNSS receiver ensures accurate mapping with minimal ground control points. WingtraONE GEN II Specs / Features: Camera Sensor: 42 megapixel Sony sensor with full-frame and low distortion lens Sensing Capabilities: Compatible with various Sony and MicaSense sensors Flight Time: 59 minutes Flight Speed: 16 m/s (36 mph) Transmission System: Direct line-of-sight up to 10 km (6 miles) The SenseFly eBeeX is a fully autonomous fixed-wing drone capable of covering vast areas with minimal input. Weighing just 3.6 pounds, it can fly up to 1200 acres per mission and supports nine different cameras for various applications. Its user-friendly eMotion software simplifies mission planning and data analysis, making it ideal for large-scale mining operations. SenseFly eBeeX Specs / Features: Camera Sensor: Choose from 9 sensors, including RGB, thermal, and multispectral options Sensing Capabilities: Compatible with various SenseFly and MicaSense sensors Flight Time: 90 minutes Flight Speed: 30 m/s (68 mph) Transmission System: Flight range of 37 km (23 miles) The DJI Phantom 4 RTK is a popular choice for outdoor mining applications. It features a 20-megapixel CMOS sensor with a mechanical shutter, ideal for accurate mapping and surveying. The built-in RTK module ensures centimeter-level accuracy, making it perfect for medium-sized mine sites. With a flight time of 30 minutes and a transmission range of 7 km (4.3 miles), it offers a balance of performance and reliability. DJI Phantom 4 RTK Specs / Features: Camera Sensor: 20 megapixels with 4K video resolution Flight Time: 30 minutes Flight Speed: 13 m/s (31 mph) in P-Mode / 16 m/s (36 mph) in A-Mode Transmission System: DJI OcuSync DJI Phantom 4 RTK DroneDeploy is a leading platform for mining and quarry applications. It uses aerial data to improve efficiency, accuracy, and safety in stockpile management, mine planning, and compliance. Its intuitive interface allows teams to manage operations from a central dashboard. Top Features: Stockpile Inventory Management Mine Planning and Excavation Safety and Compliance Centralized Operations Management Pix4D is another top choice for drone mapping and 3D modeling in mining. It provides tools for geotechnical hazard forecasting, stockpile volume calculation, and asset lifecycle management. Its high-resolution 3D maps help teams make informed decisions quickly. Top Features: Forecast geotechnical hazards Accurate and automatic stockpile volume calculation Asset lifecycle management Generate high-resolution interactive 3D maps Propeller’s software enables teams to collect high-accuracy data and generate 3D models that are easy to share and analyze. It streamlines the entire surveying process, making it faster and more efficient. Top Features: Quick and frequent drone surveys Complete documentation of project lifecycle Simplified inventory management Collaboration and communication Skycatch offers a comprehensive suite of tools for drone data automation, processing, and analysis. It includes onboarding, training, and ongoing support to help users get the most out of their drone operations. Top Features: Fastest time-to-data in the market Eliminates GCPs for safer data capture Proven 5 cm accuracy across all axes Process offline in the field or in the cloud Precise, high-fidelity 3D models of vertical surfaces Skycatch software Application: High-Altitude Underground Mining Inspection Mission: Demonstrate the ability of the Elios 2 to cut down costs and improve safety in a high-altitude oxygen-depleted mine environment. Results: The Volcan team conducted 40 flights with the Elios 2, inspecting chimneys, ore passes, ventilation tunnels, and stopes. 3D maps were created using Pix4D mapping software, and all planned inspections were successful. Significance: The Elios 2 was able to operate where no other drone could. By using a drone to navigate the mine, miners save time and money while ensuring safety. [Read the full case study here: Testing the Elios 2 at a High Altitude Mine Located in the Andes Mountains] Application: Mine / Quarry Monitoring and Operational Planning Mission: Reduce operating expenses by integrating a fixed-wing mine drone into surveying operations. Results: The Jellinbah Group found a significant decline in operational expenses and time. The fixed-wing platform also eliminated inefficiencies seen with quadcopters. Significance: Large mining sites can now use fixed-wing drones, which are more efficient than multirotor drones. The VTOL feature allows surveys to be conducted anywhere. Application: Quarry Monitoring and Operational Planning Mission: Survey the largest limestone quarry in a day. Results: The quarry was split into three segments, and the eBeeX captured over 6,000 high-resolution images in a few hours, creating detailed orthomosaic images and 3D models. Significance: Surveying a site of this size used to take up to two months. Now, it can be done in a single day, significantly reducing delays and risks. Application: Quarry Drilling and Blasting Mission: To identify how a customized drone solution for mining can deliver the safest, controlled, and cost-efficient execution of a scheduled blast operation in a quarry mine. Results: The DJI Matrice 300 RTK and Zenmuse H20T cameras performed well in terms of control and decision-making. Significance: Using drones in mining combines the knowledge of miners with digital intelligence, resulting in safer and more cost-effective operations. Application: Stockpile Volumetry Mission: Improve the accuracy of volumetric stockpile measurements to increase safety and reduce expenses for Granite Construction. Results: Using DroneDeploy, the company achieved accuracy comparable to traditional methods in a fraction of the time. All volume calculations were within 1% of alternatives. Significance: Aerial volumetric software is faster, safer, and half the cost of traditional ground-based methods. Smco Magnets,High Temp Magnets,Samarium Cobalt Magnets,Samarium Cobalt Magnet Rod Anfeng Industrial Co.,Ltd , https://www.afmagnets.com6 Ways Mine Drones Are Being Used

What Is a Mine Drone?

Aerial drone footage of a surface coal mine

Aerial drone footage of a surface coal mine1. Volumetric Monitoring

Processing overburden into stockpiles

Processing overburden into stockpiles2. Identifying Hazards

3. Drilling and Blasting Assessment

Drilling holes for explosives

Drilling holes for explosives4. Mine Monitoring and Planning

5. Mine Development and Exploration

6. Processing Plant Inspections

The Benefits of Drones in Mining

The Best Indoor Mine Drone on the Market

Elios 3

Elios 3Best Fixed Wing Outdoor Mine Drones on the Market

WingtraOne GEN II

WingtraOne Gen II

WingtraOne Gen IISenseFly eBeeX

SenseFly eBeeX

SenseFly eBeeXBest Multicopter Outdoor Mine Drone on the Market

DJI Phantom 4 RTK

Best Mine Drone Software

DroneDeploy

DroneDeploy software | Medium

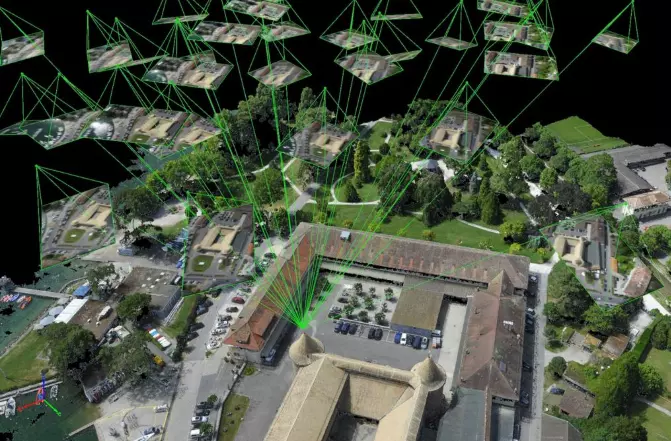

DroneDeploy software | MediumPix4D

Pix4D software

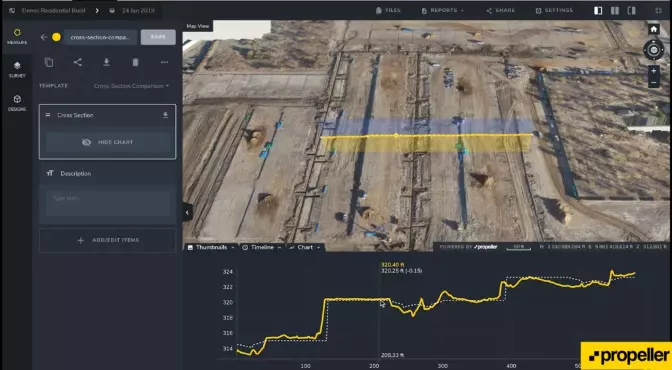

Pix4D softwarePropeller

Propeller software

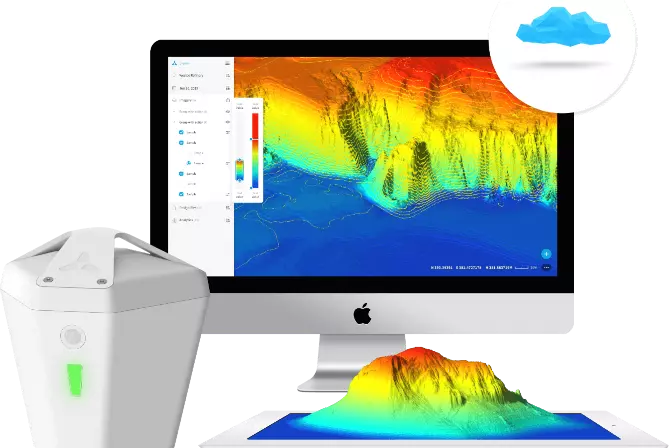

Propeller softwareSkycatch

Mining Drone Case Studies

Flyability Elios 2 — Inspection

Wingtra— Survey

SenseFly— Survey

DJI— Survey

DroneDeploy— Stockpile Measurement