How Mine Drones Are Improving Safety and Optimizing Mining

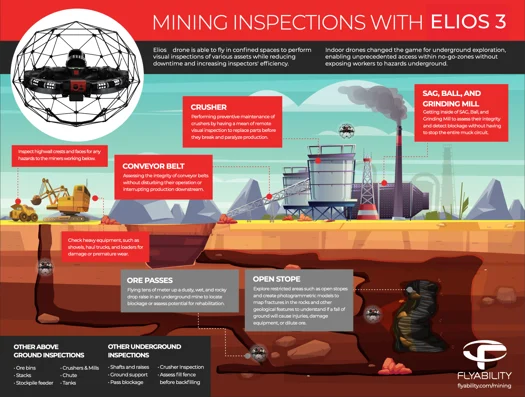

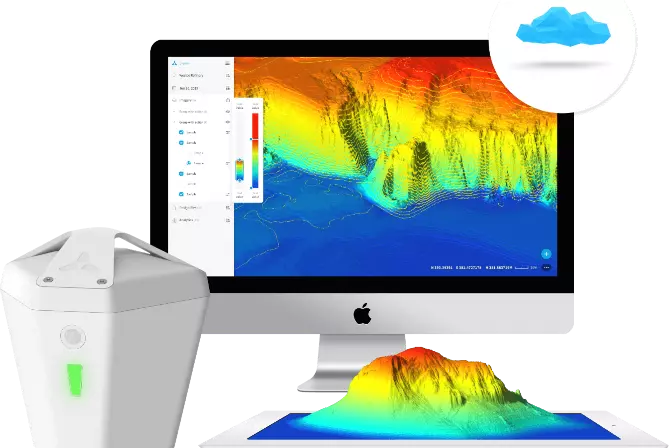

Mine drones are revolutionizing the mining industry by offering a safer, more efficient, and cost-effective way to perform critical tasks. As technology continues to evolve, these aerial tools are becoming essential in both underground and surface mining operations. A mine drone is a specialized unmanned aerial vehicle (UAV) designed for use in mining environments. These drones are used for tasks such as stockpile measurement, surveying, mapping, and even ultrasonic thickness testing. Mining is inherently dangerous, with unpredictable conditions that can pose serious risks to workers. While drones cannot eliminate all dangers, they can collect data from areas where human access is limited or unsafe. One key advantage of mine drones over standard consumer drones is their ability to operate without GPS, which is often unavailable in underground mines. This makes them ideal for navigating complex and hazardous environments. The mining sector has rapidly adopted drone technology due to its ability to enhance data collection, improve safety, and reduce operational costs. Here are six major applications of mine drones: Volumetric monitoring involves calculating the amount of material in stockpiles, such as overburden, ore, or other mining materials. Traditional methods are time-consuming and inaccurate, especially with large stockpiles. Mine drones provide quick, reliable volume data using photogrammetry or LiDAR scans. This helps track material changes, optimize waste management, and support better planning. Mining environments are filled with hazards like unstable rock formations, gas leaks, dust explosions, and chemical exposure. Drones help identify these risks without putting workers in harm’s way. They can inspect surface stockpiles for instability or explore underground tunnels to detect blockages and structural weaknesses. The Elios 3, for example, is specifically designed for tight, dark, and hazardous underground spaces. Drones play a crucial role in assessing drilling and blasting activities. Before any operation begins, 3D models created from drone data can be used to evaluate potential impacts. Afterward, updated models help analyze the effectiveness of blasting techniques and ensure safe re-entry into the area. This improves decision-making and enhances situational awareness. Mine drones are used extensively in monitoring and planning. They assist in designing haulage roads, conducting equipment inspections, improving site security, and monitoring environmental impacts. For instance, drones can assess road conditions, check conveyor belts for wear, and monitor tailings dams to prevent leaks. Their ability to cover large areas quickly makes them an invaluable tool for ongoing mine management. Exploring new mining sites or investigating old ones can be dangerous and costly. Drones allow for safe and efficient exploration of inaccessible areas. They can map out disused parts of a mine, helping to avoid potential collapses or gas buildups. The Elios 3 is particularly suited for confined underground spaces where visibility and air quality are poor. In processing plants, drones are used to inspect machinery without interrupting operations. They can check for wear on feeders, detect cracks in welds, measure tank thicknesses, and monitor conveyor belt temperatures. This leads to more efficient maintenance, reduced downtime, and improved safety for workers. As drone technology advances, so do the benefits for the mining industry. Drones offer faster data collection, improved accuracy, and enhanced safety. They also reduce the need for manual labor and minimize the risk of accidents. With real-time data and detailed 3D models, mining companies can make smarter decisions and operate more efficiently. Some key advantages include: Watch the Elios 3 inspect and map an obstructed ore pass:  Among the many drones available, the Flyability Elios 3 stands out for its durability, functionality, and advanced features. Designed for indoor and confined spaces, it offers collision tolerance, high-resolution imaging, and real-time 3D mapping. Its dual thermal and 4K camera system ensures accurate data collection, even in low-light conditions. The Elios 3 is ideal for inspecting tunnels, shafts, and other hard-to-reach areas. It supports modular payloads, including LiDAR and ultrasonic sensors, making it highly versatile for various mining applications. Flyability Elios 3 Specs / Features: The WingtraOne GEN II is a powerful fixed-wing drone designed for large-scale mining operations. It offers extended flight times, high-speed performance, and precise mapping capabilities. With a 42-megapixel camera and vertical takeoff and landing (VTOL) system, it can cover vast areas quickly and efficiently. WingtraONE GEN II Specs / Features: The eBeeX is a fully autonomous drone capable of covering large areas with minimal input. It can fly up to 1200 acres per flight and supports a wide range of sensors, making it suitable for various mining tasks. Its user-friendly software allows for easy mission planning and execution. SenseFly eBeeX Specs / Features: The DJI Phantom 4 RTK is a top choice for outdoor mining operations. It features a high-resolution 20-megapixel camera, long-range transmission, and built-in RTK for precise geolocation. Ideal for medium-sized sites, it provides accurate data for mapping and surveying. DJI Phantom 4 RTK Specs / Features: DJI Phantom 4 RTK DroneDeploy is a leading platform for mining and quarry operations, offering tools for mapping, stockpile management, and mine planning. It enables teams to create detailed 3D models and streamline data analysis. Top Features: Pix4D specializes in drone-based 3D modeling and mapping solutions. It helps mining companies forecast geotechnical risks, calculate stockpile volumes, and generate high-resolution maps for better decision-making. Top Features: Propeller's software is designed to capture high-accuracy data and generate 3D models that can be shared across teams. It streamlines workflows and improves collaboration in mining projects. Top Features: Skycatch offers automation and analytics tools for aerial data collection. It simplifies the process of capturing, processing, and analyzing drone data, making it ideal for mining applications. Top Features: Skycatch software Application: High-Altitude Underground Mining Inspection Mission: Demonstrate the ability of the Elios 2 to cut down costs and improve safety in a high-altitude oxygen-depleted mine environment. Results: The Volcan team conducted 40 flights with the Elios 2, creating 3D maps using Pix4D software. All planned inspections were successful, proving the drone's effectiveness in challenging conditions. Mine Drone Significance: The Elios 2 operates where no other drone can, allowing miners to save time and money while keeping workers safe. Application: Mine / Quarry Monitoring and Operational Planning Mission: Reduce operating expenses by integrating a fixed-wing mine drone into surveying operations. Results: The Jellinbah Group saw significant cost and time savings, with the WingtraOne drone enabling on-demand surveys. Mine Drone Significance: Large mining sites now have a more efficient and flexible option for aerial surveys. Application: Quarry Monitoring and Operational Planning Mission: Survey the largest limestone quarry in a day. Results: The eBeeX drone captured over 6,000 images in a few hours, creating detailed 3D models and orthomosaics. Mine Drone Significance: Drones significantly reduce the time and risk involved in large-scale surveys. Application: Quarry Drilling and Blasting Mission: Use a customized DJI solution to safely execute a scheduled blast operation. Results: The DJI Matrice 300 RTK and Zenmuse H20t cameras provided accurate control and real-time data for decision-making. Mine Drone Significance: Combining miner expertise with drone intelligence improves safety and reduces costs. Application: Stockpile Volumetry Mission: Improve the accuracy of volumetric stockpile measurements for Granite Construction. Results: Using DroneDeploy, the company achieved accuracy within 1% of traditional methods, saving time and costs. Mine Drone Significance: Aerial volumetric software is faster, safer, and half the cost of ground-based methods. Disc Magnets,Thin Disc Magnets,Neodymium Disc Magnets,Strong Rare Earth Magnets Anfeng Industrial Co.,Ltd , https://www.afmagnets.com6 Ways Mine Drones Are Being Used

What Is a Mine Drone?

Aerial drone footage of a surface coal mine

Aerial drone footage of a surface coal mine1. Volumetric Monitoring

Processing overburden into stockpiles

Processing overburden into stockpiles2. Hazard Detection

3. Drilling and Blasting Assessment

Drilling holes for explosives

Drilling holes for explosives4. Mine Monitoring and Planning

5. Mine Development and Exploration

6. Processing Plant Inspections

The Benefits of Drones in Mining

The Best Indoor Mine Drone on the Market

Elios 3

Elios 3Best Fixed Wing Outdoor Mine Drones on the Market

WingtraOne GEN II

WingtraOne Gen II

WingtraOne Gen IISenseFly eBeeX

SenseFly eBeeX

SenseFly eBeeXBest Multicopter Outdoor Mine Drone on the Market

DJI Phantom 4 RTK

Best Mine Drone Software

DroneDeploy

DroneDeploy software | Medium

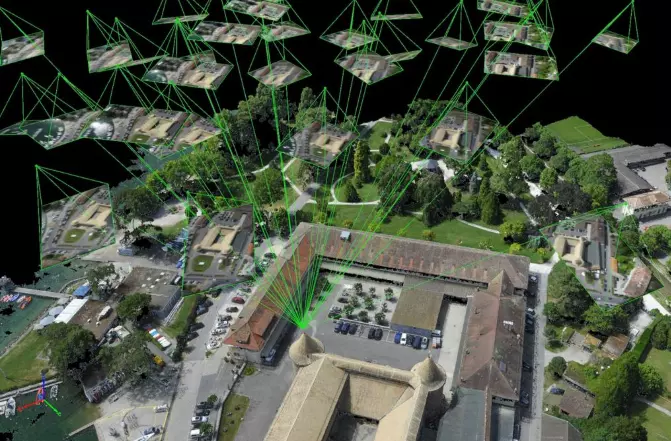

DroneDeploy software | MediumPix4D

Pix4D software

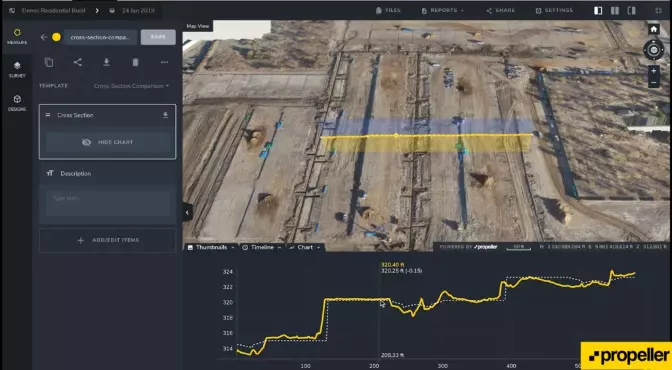

Pix4D softwarePropeller

Propeller software

Propeller softwareSkycatch

Mining Drone Case Studies

Flyability Elios 2 — Inspection

Wingtra— Survey

SenseFly— Survey

DJI— Survey

DroneDeploy— Stockpile Measurement