An Intro to Quick Connect Fittings and Their Uses

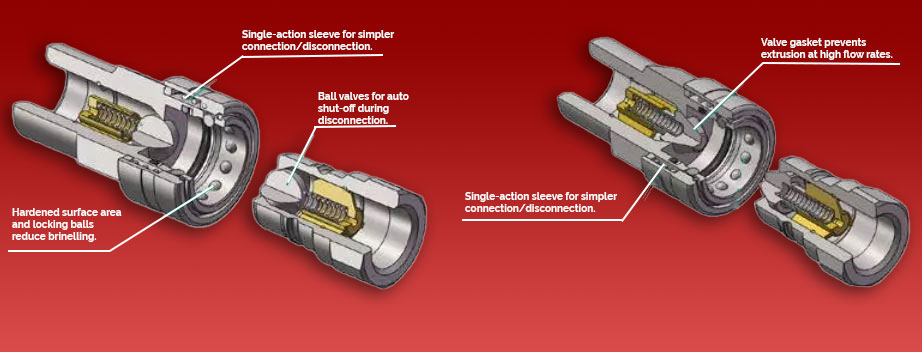

In the fast-paced world of hydraulic systems, efficiency and reliability are key. Among the many components that contribute to this, quick connect hydraulic fittings stand out as a game-changer. These fittings are designed to enable fast and secure connections between hydraulic lines, making maintenance easier and system operation smoother. Let’s take a closer look at how these fittings work and why they are so important in modern hydraulic applications. The design of quick connect fittings is both simple and effective. They typically consist of two parts: a male plug and a female coupler. When the male plug is inserted into the female coupler, an internal locking mechanism—often made up of ball bearings or similar components—engages automatically, securing the connection. This process usually requires just a push, and the fitting locks in place with a distinct click, ensuring a tight seal and preventing fluid leaks. To disconnect, you simply press or pull a release button or sleeve on the female end, which disengages the lock and allows the male plug to be pulled out easily. This feature makes it possible to quickly assemble or disassemble hydraulic lines without the need for tools, saving time and reducing downtime during maintenance or system adjustments. When selecting quick connect fittings, the material used plays a crucial role in determining their performance and longevity. Common materials include brass, which is known for its good corrosion resistance and conductivity; plastic, which is lightweight and cost-effective, often used in less demanding environments; and stainless steel, which offers superior strength, durability, and resistance to corrosion. Stainless steel fittings are especially popular in harsh conditions where exposure to extreme temperatures or corrosive fluids is common. They maintain their structural integrity under high pressure and resist wear over time, making them ideal for heavy-duty applications. In addition to material choice, the design of the fittings can vary, from basic straight connectors to more complex shapes like elbows or tees, allowing for better routing and space optimization within hydraulic systems. Quick connect fittings have become an essential part of modern hydraulic systems due to their versatility, efficiency, and ability to enhance system performance. Their tool-free design allows for rapid connections and disconnections, reducing downtime and improving productivity across various industries. Whether in construction, manufacturing, or automotive applications, these fittings offer a reliable and safe solution for managing fluid power. With their robust construction and ease of use, quick connect fittings continue to evolve, offering even greater benefits to engineers and technicians who rely on efficient hydraulic systems. Answer: Hydraulic quick couplers are designed to allow fast and secure connections in hydraulic systems. They consist of two parts: a male plug and a female coupler. Each has a built-in valve that remains closed until the two parts are connected. When the male plug is pushed into the female coupler, the valves open, allowing fluid to flow through. A locking mechanism inside the coupler holds the plug in place, while seals ensure a leak-proof connection. To disconnect, you press a release button or pull a sleeve, which closes the valves and releases the male plug. These couplers are ideal for situations where frequent and easy connections are needed, offering convenience, safety, and minimal fluid loss. Answer: To safely disconnect quick connect fittings, locate the release mechanism on the female coupler, which could be a button, ring, or sleeve. Before disconnecting, make sure the hydraulic system is fully depressurized to avoid any risk of injury or damage. Once the system is safe, engage the release mechanism by pressing or pulling it. While holding the release in place, gently pull the male plug out of the female coupler. After disconnection, inspect both parts for any signs of wear or damage. If necessary, replace the fittings to ensure future connections remain secure and leak-free. Always follow the manufacturer's instructions, as different designs may have specific steps to ensure proper use and safety. Automobile Checking Fixture,Laser Cutting Parts Machining,Motor Block Cnc Machining,Stainless Steel Cnc Machining Part JING SUNG Precision CO., , https://www.jingsungcnc.comQuick Connect Fittings: Enhancing Efficiency in Hydraulic Systems

The Simple Mechanics Explained

Materials Matter: Choosing the Right Quick Connect Fittings for Your Hydraulic System

Conclusion

Frequently Asked Questions:

How do hydraulic quick couplers work?

How to disconnect quick connect fittings?