Remote Hull inspection saves $1 million with the Elios 3

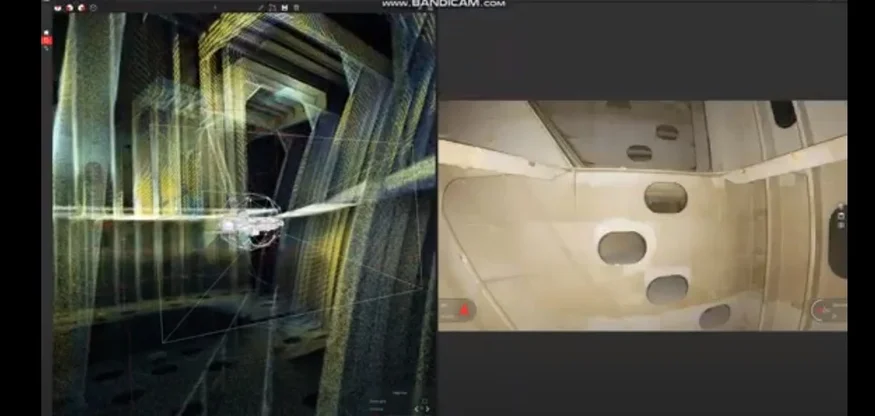

C-Bird used the Elios 3 to conduct a hull inspection on a cargo ship, achieving results that were safer, faster, and more efficient than ever before. SAFETY: By using the Elios 3 for the hull inspection, C-Bird eliminated the need for scaffolding in cargo tanks, avoiding approximately 10,000 hours of work at height in confined spaces. COST SAVINGS: Replacing scaffolding with the Elios 3 during the vessel survey resulted in a direct cash saving of around $1 million, along with significant time and logistics savings. ENVIRONMENTAL IMPACT: Using a drone instead of rafting for inspections avoided the creation of large volumes of oil-contaminated water, which would require treatment before disposal. DATA QUALITY: The onboard LiDAR on the Elios 3 provided accurate data localization, making it easier to share findings with all stakeholders during the survey. Over 90% of the world's cargo vessels are subject to the IACS Common Structural Rules (CSR), which set strict standards for design, construction, and maintenance. These rules ensure that ships meet safety and structural integrity requirements throughout their operational life. Vessels must renew their classification every five years, and a major part of this process is the hull survey, which assesses the structural condition of the ship. Crude oil tankers face particularly challenging inspection conditions, as much of the structure inside the cargo oil tanks (COT) is difficult to access. Traditionally, this required either building scaffolding or filling the tanks with water for a process called rafting — both of which come with high costs and risks. The scale of a cargo tank is immense — scaffolding here can rise tens of meters, making detailed inspections very challenging. As ships age, the cost of these inspections increases significantly. For vessels over 15–20 years old, the cost of erecting scaffolding alone can exceed $1 million, often representing a large portion of the total project cost for class renewal. Building scaffolding not only increases safety risks for workers but also poses operational risks to the vessel. Foreign objects like scaffold tubes or tools left behind can damage cargo pumps, leading to unplanned outages. Rafting, on the other hand, creates environmental challenges due to the large volume of contaminated water that must be treated and disposed of properly. A US-based oil tanker fleet operator needed to conduct a No. 4 Special (20-year-old) periodical survey on one of its tankers. The 250-meter vessel, classified by the American Bureau of Shipping (ABS), was undergoing dry docking in Southeast Asia for class renewal and other maintenance tasks. This operator has long been a leader in marine robotics innovation and had previously used C-Bird’s services for hull inspections with the Elios 2. Their experience showed that drones could significantly reduce the need for scaffolding and staging during class surveys. The goal was to complete the hull survey using the Elios 3 without any personnel entering the cargo tanks, minimizing risk while collecting all necessary data. Initially, an underwater ROV was considered, but after evaluating options, C-Bird chose the Elios 3 for its superior performance in this environment. C-Bird pilot Malcolm Connolly, who had used the Elios 2 before, opted for the new Elios 3 for this specific mission. He wanted to take advantage of the LiDAR live map feature, which helped navigate areas where the drone was out of sight. He also tested the new UT payload for ultrasonic thickness measurements. Malcolm guides the drone through the empty space during the hull inspection. The Elios 3 was flown into the cargo tanks without any human entry. Malcolm navigated the entire hull, capturing 4K video footage and simultaneous 3D LiDAR scans of the structures. The data was then processed in Inspector 4, creating a full 3D model of the inspected area along with clear visual documentation. The Elios 3 combines LiDAR data with real-time video feed for precise inspection. The Elios 3’s 3D Live Map allowed the C-Bird team to fully cover the required areas without entering the cargo tanks, ensuring safety from the ship’s deck. This eliminated the need to haul equipment in and out of the tanks, reducing the risk of dropped objects and lowering manual handling requirements. Malcolm Connolly, CEO of C-Bird, emphasized the benefits of the Elios 3: “The 3D laser scan allows for accurate data localization, bringing us closer to true risk-based asset management and automation. Reliable data localization means we can repeat surveys precisely, measure changes over time, and even use machine learning to predict maintenance needs. That’s the future of the industry.†He also highlighted several key advantages: full coverage of the tank with the 3D map, improved safety by reducing human entry into confined spaces, significant cost savings, and the ability to operate in extreme temperatures up to 45°C. Thanks to the Elios 3, C-Bird completed a safer, faster, and more efficient hull inspection. By eliminating the need for scaffolding, they saved over 10,000 hours of working at height. C-Bird and their client both appreciated the simplified logistics and reduced environmental impact, as no contaminated water was used. They also found the drone to be a viable alternative to traditional methods like underwater ROVs. The Elios 3 provided enough accurate data for the class renewal, helping the ship get reclassified successfully. This case study shows how drone technology is continuously evolving to meet the growing demands of the maritime industry, offering safer, smarter, and more sustainable solutions. Transshipment System,Movement Flexibility Use,Limited Area Can Wokring,Customized Lay and Size Changzhou Fuku Precision Machinery Co., Ltd. , https://www.fukuindustrial.comRemote Hull Inspection Saves $1 Million with the Elios 3

Key Benefits in a Nutshell

Seeking a Safer and More Efficient Inspection Method

How the Elios 3 Transformed the Hull Inspection Process

Why the Elios 3 Is Revolutionizing Maritime Inspections

Transforming Hull Inspections with Drone Technology